In the electronics and automotive electronics industryen the finaln Inspectionen of end devices or housings often still manually. An automated solution is offered by our AI baseds AVI Completesystem “KITOV“, for a fully automatic visual inspection the Terminal Assembly.

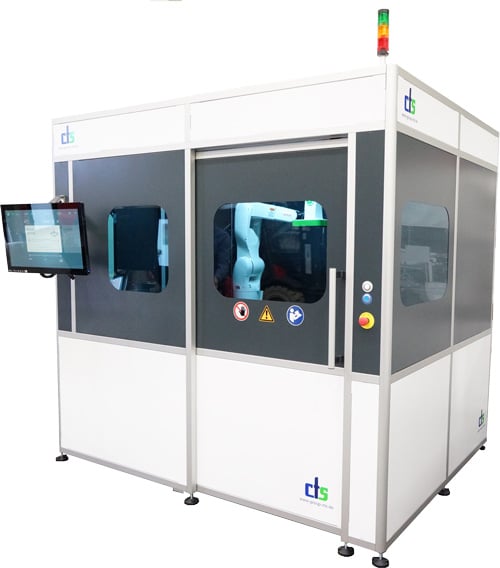

Together with our partner ATECare, we offer KITOV ONE, the first smart 3D universal system that can effectively inspect virtually any product. Using advanced 3D computer vision algorithms and artificial intelligence, such as machine learning and deep learning, KITOV ONE achieves unprecedented levels of recognition.

The KITOV ONE supports complex 3D structures, numerous materials and complete test specifications.

The advantages of the KITOV AVI complete system:

Overview,

Videos and

more links

Our solutions are customizable. Talk to us!

More. Than. Automation.

cts GmbH

Fuhrmannstr. 10

D-84508 Burgkirchen

Phone: +49 8679 91689 0

Fax: +49 8679 91689 120

info@group-cts.de

cts GmbH | Copyright 2022

Geben Sie hier Ihre Suchbegriffe ein.