The company offers the highest level of expertise in all areas of process and production automation as well as advanced solutions in industrial data processing and energy technology.

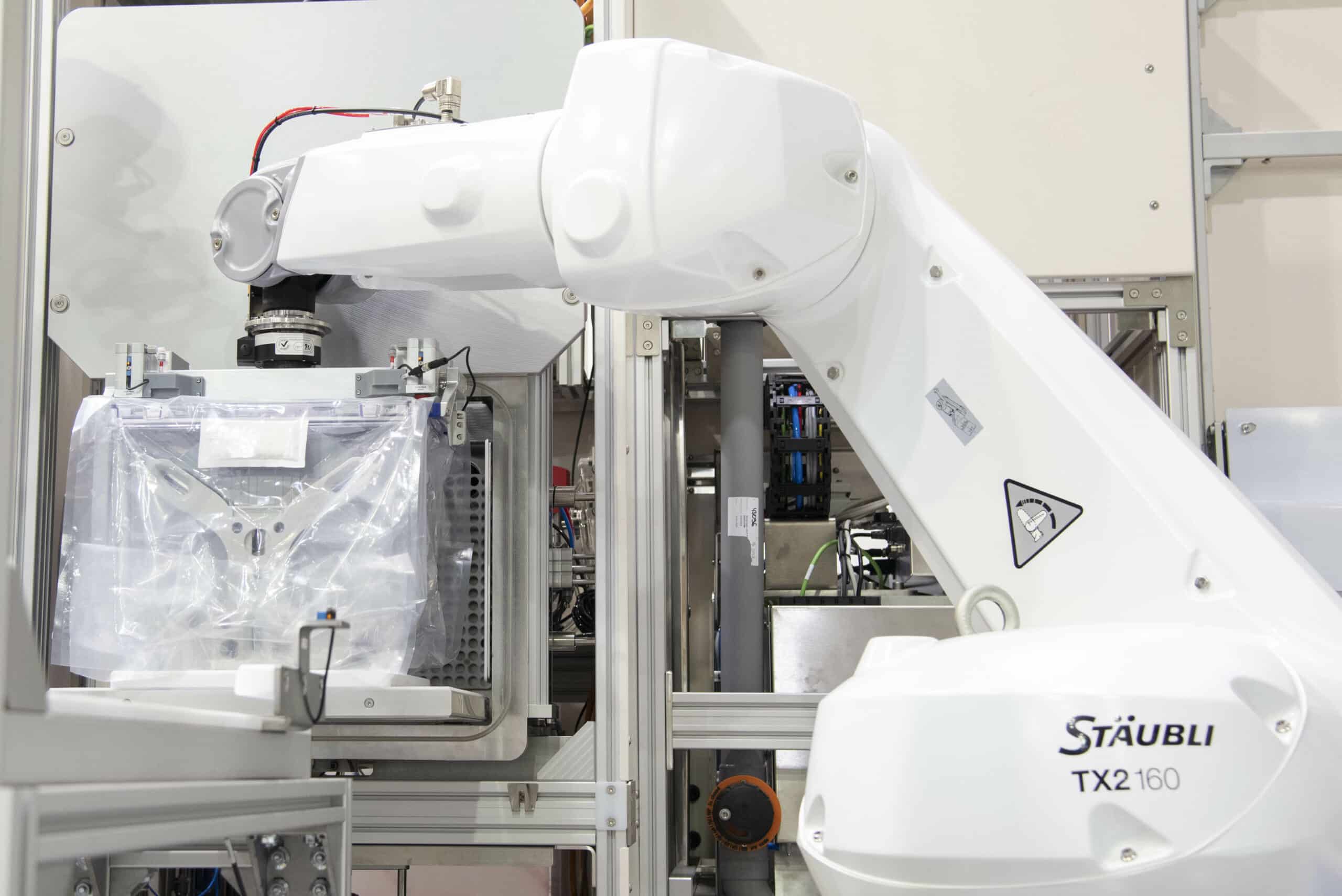

cts GmbH has developed comprehensive automation solutions for the growing electronics and semiconductor industries. The AutoBagging Tool (ABT) for fully automatic packaging from FOSB significantly increases throughput and also offers a considerable increase in quality and safety during packaging. “The airtight packaging of products for transportation to a processing plant is a complex process and is subject to the strictest criteria. cts was able to fully automate this packaging process,” reports authorized signatory Alfred Pammer proudly.

“With this innovative solution, we achieve a significant increase in quality and also relieve the burden on employees enormously. Our aim is to develop high-tech solutions and set new standards.

Electronics manufacturing 4.0

With the cts “Smart Factory”, the company is setting new standards in the field of automation in the electronics industry.

“Starting with incoming goods with complete reel recording and storage in the Gigaflex Storage Center, through to buffering the PCB magazines in the Smart Warehouse and Mini Smart Warehouse, cts also offers solutions,” explains Philipp Eberherr, responsible for intralogistics solutions at cts. “We are experts in smart intralogistics and support customers as a reliable partner in the transformation to the smart factory.”

With the Gigaflex Reel Storage, cts Smart Warehouse and Mini Smart Warehouse storage solutions, cts offers an intelligent, modular and highly effective option for storing component reels and PCB magazines. Thanks to the significant reduction in store floor occupancy, these enable valuable space to be saved in the production area. The customized mini buffer solutions (cts transfer stations) reliably compensate for small asynchronies in the production process.

Optimized material flow in the smart factory

“The material flow can be optimized with the automatic supply of storage solutions and systems by AMRs of different sizes and load capacities. It also makes the process more flexible and reliable and enables traceability,” explains Alfred Pammer.

The use of different AMRs, sometimes from several manufacturers, is easily possible with the cts middleware sloXis®. sloXis® combines all the elements of a modern industrial system: from AMRs from various manufacturers with different functionalities to small buffers and smart warehouses. The software forms the central interface to the MES/ERP. Nothing stands in the way of the conversion of electronics production to a smart factory! (red./PR)

Link to the article: New Business – Magazine for entrepreneurs