Interview with Alfred Pammer, authorized signatory/head of sales and marketing at cts GmbH

Having already successfully developed and implemented intelligent automation solutions for warehouse applications under the motto ‘Smart Warehouse’, the automation specialist cts GmbH from Burgkirchen in southern Bavaria is now taking the next logical step and turning its attention to material flow throughout the entire production process. Under the motto ‘Smart Factory’, the company is expanding its proven combination of hardware and software into solutions that meet its customers’ needs for greater efficiency and productivity. In an interview with Wirtschaftsforum, Alfred Pammer, Authorized Signatory/Head of Sales and Marketing at cts GmbH, describes the development of the intelligent factory of tomorrow.

Wirtschaftsforum: Mr. Pammer, what is the idea behind the Smart Factory?

Alfred Pammer: The aim of the Smart Factory is to make work easier for employees, make working hours more efficient and avoid errors. For us, it’s about closing existing gaps in the automation of the production process. We are building on our existing portfolio with new solutions.

Business Forum: What will the smart factory of tomorrow look like?

Alfred Pammer: At the heart of the Smart Factory are our storage and buffer solutions, which we have been using successfully in the electronics and semiconductor industry since 2019 to store the required production materials in a space-saving manner and close to production. Our cts Smart Warehouse was designed to create as much storage capacity as possible in as little space as possible. In its largest configuration, we can accommodate up to 1,100 PCB magazines on a footprint of just 20 x 4.5 meters.

We achieve this by going 4.3 m upwards. However, the size of the Smart Warehouse can be customized according to requirements.

Business Forum: How is the content of the Smart Warehouse fed into the production flow?

Alfred Pammer: We have been working in the field of mobile robotics since 2015 and have developed solutions for transporting PCB magazines, KLT boxes and stackable containers as well as pallets. So-called AMRs (autonomous mobile robots) are used to bring the required goods to the production line in a highly flexible manner. In conjunction with the Smart Warehouse, the AMRs ensure the automatic supply and disposal of the production line.

Wirtschaftsforum: Are such solutions also profitable for smaller companies?

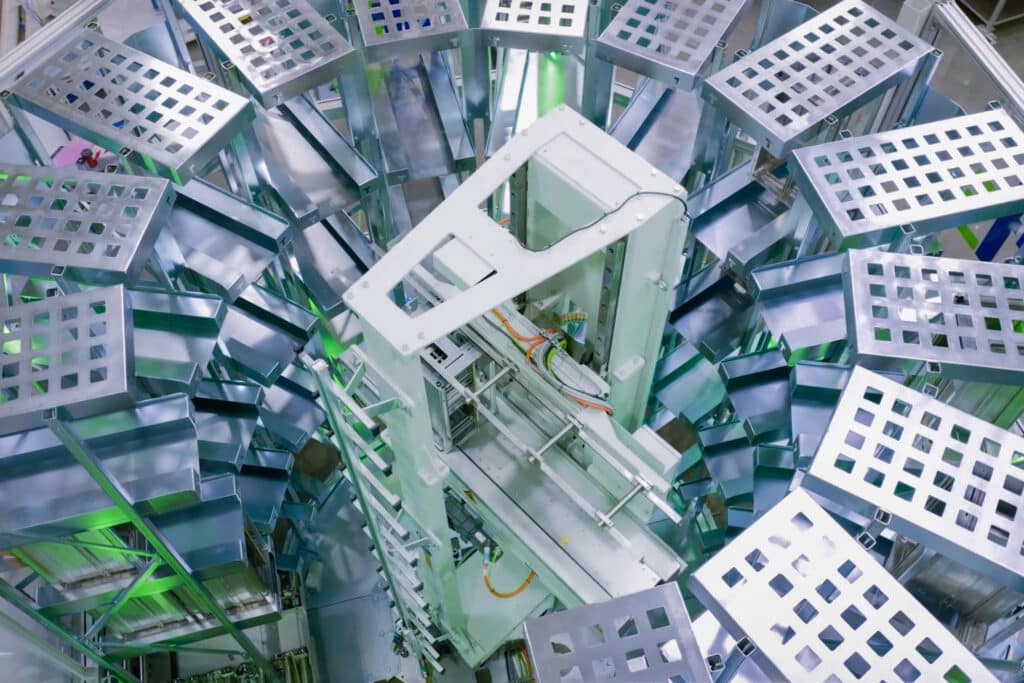

Alfred Pammer: We responded to the increasing number of requests from small and medium-sized customers for smaller solutions and launched our Mini Smart Warehouse in 2021. It closes an important gap in the market and is aimed at companies with a storage requirement of less than 300 magazines. Thanks to its octagonal shape, this is achieved on a particularly small footprint of just 4.2 x 4.2 m or 4.8 x 4.8 m. In this case, the internal handling unit does not move from left to right like its big brother, but in a circle to reach all storage compartments.

Economic Forum: What gaps still need to be closed?

Alfred Pammer: The overall package is particularly important in the electronics industry. We recently launched our new Gigaflex Reel Storage Center this year. When assembling printed circuit boards, the components are supplied on reels. These must first be stored temporarily. Thanks to intelligent automatic picking, they are provided just-in-time from the component roll warehouse. Our solution builds on existing knowledge and sets itself apart from others by mounting the reels vertically instead of horizontally. This enables us to store 50,000 7″ rolls on a floor area of around 50 m², thus closing the final gap to the fully automated system.

Business Forum: Where do the various threads of the Smart Factory come together?

Alfred Pammer: Our cross-platform middleware sloXis® combines all elements in the production environment and acts as an intelligent data hub. In addition, the software is designed to be open so that third-party hardware can be easily integrated.

Economic Forum: How has the response been so far?

Alfred Pammer: The new system is already in operation in many places and the feedback is very positive. The further order situation is very good. We are therefore looking forward to moving into our new production facility in the first quarter of 2024. We will have expanded capacities there in order to meet our customers’ requirements even faster.

Source:

Wirtschaftsforum.de